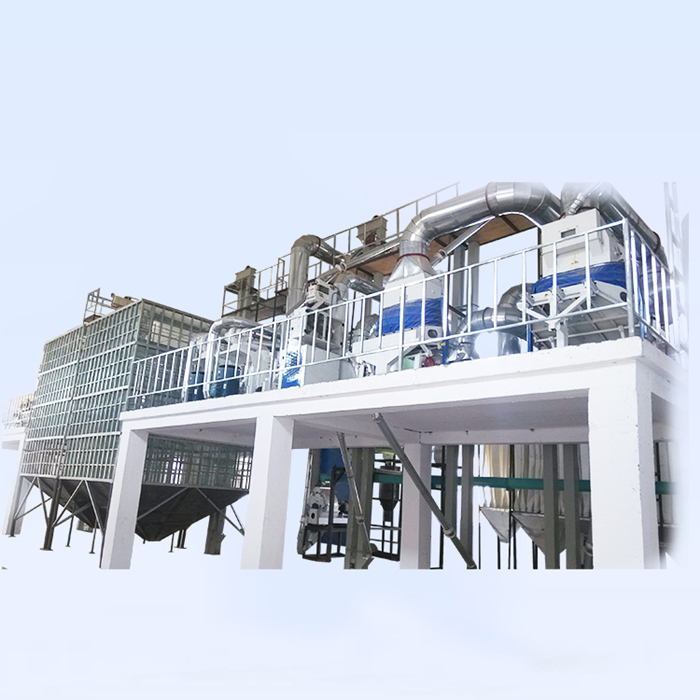

Processing line:Vibrated cleaner → Destoner → Rice husker → Rice Separator → Rice Mill → Rice polisher → Rice Grader → Rice Color Sorter → Packing&sealing.

1. Vibrated cleaner: Cleaning the paddy

2. Destoner: Separating small stones from the paddy

3. Husker: Removing the husk from the paddy

4. Separator: Separating the husk from the brown rice /unhusked paddy

5. Rice Mill: From paddy to rice

6. Rice polisher: The polishing machine will make the white rice more shining and more smooth, thus to increase the quality of rice

7. Rice grader: separate different quality rice and separate broken rice from the good ones.

8. Rice color sorter: The rice we get from above steps still have some bad rice, broken rice or some other grains or stones, so here we use color sorting machine to select the bad rice and other grains. Color sorting machine is an important machine to ensure we can get high quality rice

| 80T/24h rice milling machine | 80T | 190KW | 71% | 20*6*8.5M |

| 100T/24h rice milling machine | 100T | 249KW | 71% | 26*10*7M |